No products in the cart.

- Course No E – 1781

- PDH Units: 4

Course No E - 1781

PDH Units: 4

- Course No E – 1781

- PDH Units: 4

Course No E - 1781

PDH Units: 4

Intended Audience: mechanical and electrical engineers, operations & maintenance personnel, as well as consultants and contractors who construct, build and manage facilities.

PDH UNITS: 4

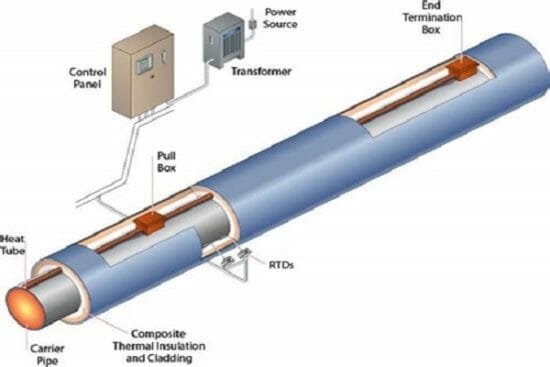

The term heat-tracing refers to the continuous or intermittent application of heating pipelines, tanks, vessels or other equipment used for storage or transportation of a product (liquid, powder or gas). The purpose of heat tracing is to compensate or make up for the heat loss to the surrounding atmosphere in low ambient temperature climates. Some applications for heat tracing include; preventing fluid from freezing, maintaining process fluids at pumpable viscosities, preventing formation of hydrates and waxes in hydrocarbon liquids (oil, etc) and also sometimes to preheat part of a fluid system prior to initial startup or after a primary heating system shutdown. The heat tracing is generally accomplished by employing electric tracing, or steam tracing and insulating both the process fluid pipe and the tracer together, using appropriate insulation materials and metal lagging. The decision between electric and steam heat tracing depends on various factors and this 4 hour course outlines the pros and cons of both the methods.

Learning Objectives

Upon completion of the course, the student should understand:- Understand what is heat tracing and where it is used;

- Understand the different types of heat tracing systems – electric, steam, hot water;

- Understand the advantages and limitations of – constant watt, parallel circuit, self regulating and skin type heating;

- Learn the control techniques – ambient air sensing or line control for optimum energy efficiency;

- Understand the power supply, protection and safety devices;

- Learn about the various codes and standards governing the design and installation of electric heat tracing;

- Understand three types of steam heat tracing systems – external tube tracers, cemented tracers and fully jacketed pipe;

- Understand do’s and don’ts of steam tracing;

- Learn step-by-step approach for estimating the heat loss and selection of an electric heat tracing system;

- Learn the key factors affecting the selection of heat tracing systems;

- Learn the factors favoring and against the application of electric and steam heat tracing systems.

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.